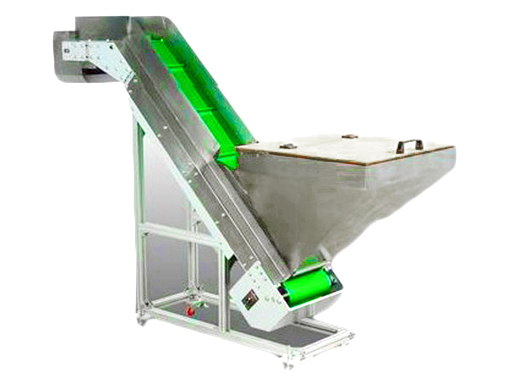

Hopper & Tray Feeder

A hopper and tray feeder system combines two essential components for efficient material handling and automated feeding in industrial applications.

Hopper: The hopper is a container designed to hold bulk materials or components. It acts as a storage unit, providing a reservoir from which items can be drawn as needed. Hoppers are typically used for accumulating and supplying a steady flow of materials to downstream processes.

Tray Feeder: Positioned beneath the hopper, the tray feeder works to regulate and dispense the contents of the hopper. It often includes a vibrating or rotating mechanism to ensure components are fed consistently and accurately onto a conveyor or directly into machinery.

Together, the hopper and tray feeder system ensures a smooth, uninterrupted supply of materials or components, optimizing production flow and reducing manual handling. This integration enhances efficiency, consistency, and reliability in various manufacturing and processing applications.

Features

These are available for augmenting the capacity of vibratory bowl feeder and increasing the manual loading time. Its capacity available her 30 to 50 liters & special feeders (according to requirements)

Supreme strength

Easy installation

Light weight